TEFISEN Pad Printing Processing Factory: Crafting Every Detail with Precision!

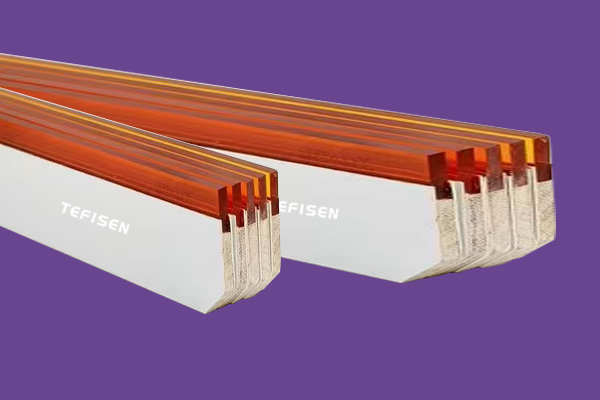

[Abstract] Pad printing is a highly efficient printing technique. As a professional pad printing machine manufacturer and processing factory, TEFISEN offers pad printing services for various materials, extensively applied in electronics, medical, automotive, and other industries. Its pad printing process includes plate-making, ink scraping, ink pickup, transfer printing, and curing. By employing precision techniques and advanced equipment, TEFISEN ensures superior printing results. TEFISEN is your preferred partner for pad printing services. I. Introduction to Pad Printing Processing Pad printing is a highly efficient printing technology that originated in Europe in the 1950s and is now widely used for printing on complex surfaces. The core of the technology lies ...