Pad Printing Pads

Detailed Introduction

1. How to Choose the Right Pad Printing Pads for You?

With thousands of pad printing pads in various shapes, how should you correctly select the one that suits your needs? The shape of the pad printing rubber head is crucial as it directly affects the rolling effect and the ink transfer efficiency.

1) Choosing by Shape:

• You need to consider whether your printing target is a flat, spherical, or curved object. For spherical or curved objects, a flatter pad printing pad should be chosen to ensure more uniform ink transfer to the object's surface. At the same time, the pad should not be too small, as this may lead to distorted image edges.

• Sometimes, too flat a pad printing pad can create air pockets between the rubber head and the printing plate, resulting in uneven ink absorption. Therefore, finding a balance is crucial; it should not be too flat or too sharp.

2)Choosing by Size:

• Generally, a larger pad printing pad can reduce image distortion. It is recommended to choose a pad size that is 20-30% larger than the printing image size to ensure that the ink can fully cover the image area.

• Of course, you also need to consider the maximum rubber head size that your pad printing machine can accommodate, the vertical distance, and the pressure applied by the pad printing machine to the pad, especially the position of the central point.

3)Choosing by Hardness:

• Generally, it is recommended to use a harder and sharper pad to ensure printing quality. However, this still needs to be considered in combination with factors such as pressure, distance, and shape. Do you want to know how to choose the hardness of pad printing pads?

2. Features of TEFISEN Pad Printing Pads:

1) Made from high-quality silicone material, TEFISEN pad printing pads have excellent ink adhesion and release capabilities, ensuring that the ink can be perfectly transferred to the object to be printed, resulting in clear and detailed image effects.

2)Good durability: Strong resistance to solvents and inks ensures a long service life and improves production efficiency.

3)Stable hardness and shape: Even after prolonged use, it can maintain its original hardness and shape, ensuring the stability and consistency of the printing effect.

Product Features:

• A full range of specifications, with over 1,000 kinds.

• Using imported raw materials, it is anti-static, anti-dragging, and anti-linting.

• Durable and wear-resistant, it does not emit oil during long-term printing, and the printing times can reach over 100,000.

• It has no shrinkage, and the oil can be easily applied and removed, resulting in clear printed patterns.

• With good elasticity and flexibility, it can transfer ink easily and meet the printing needs of various products.

• Customization is available.

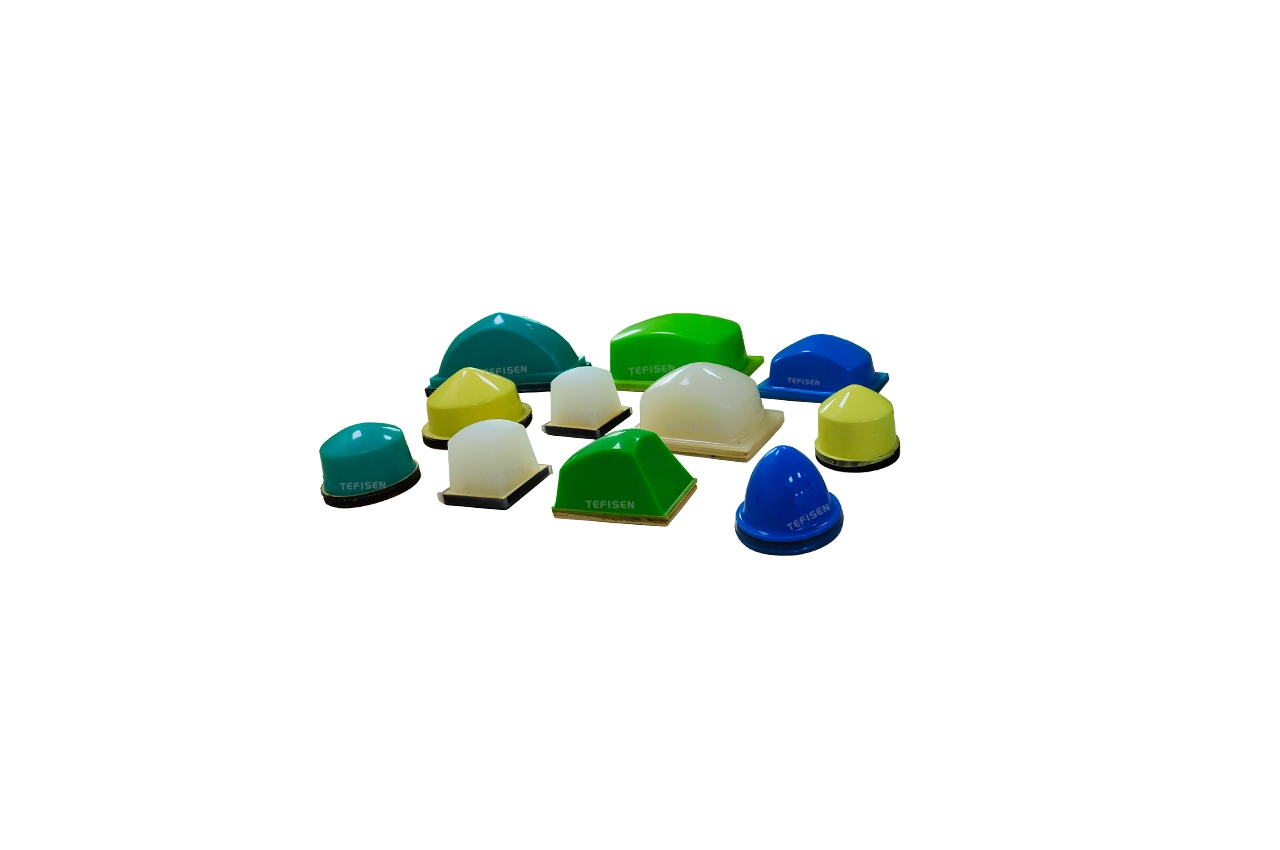

3.Round Pad Printing Pads

|

TS-Y4029 |

TS-Y3129 |

TS-Y9049 |

|

|

|

|

φ50X39(H)mm |

φ41X39(H)mm |

φ100X59(H)mm |

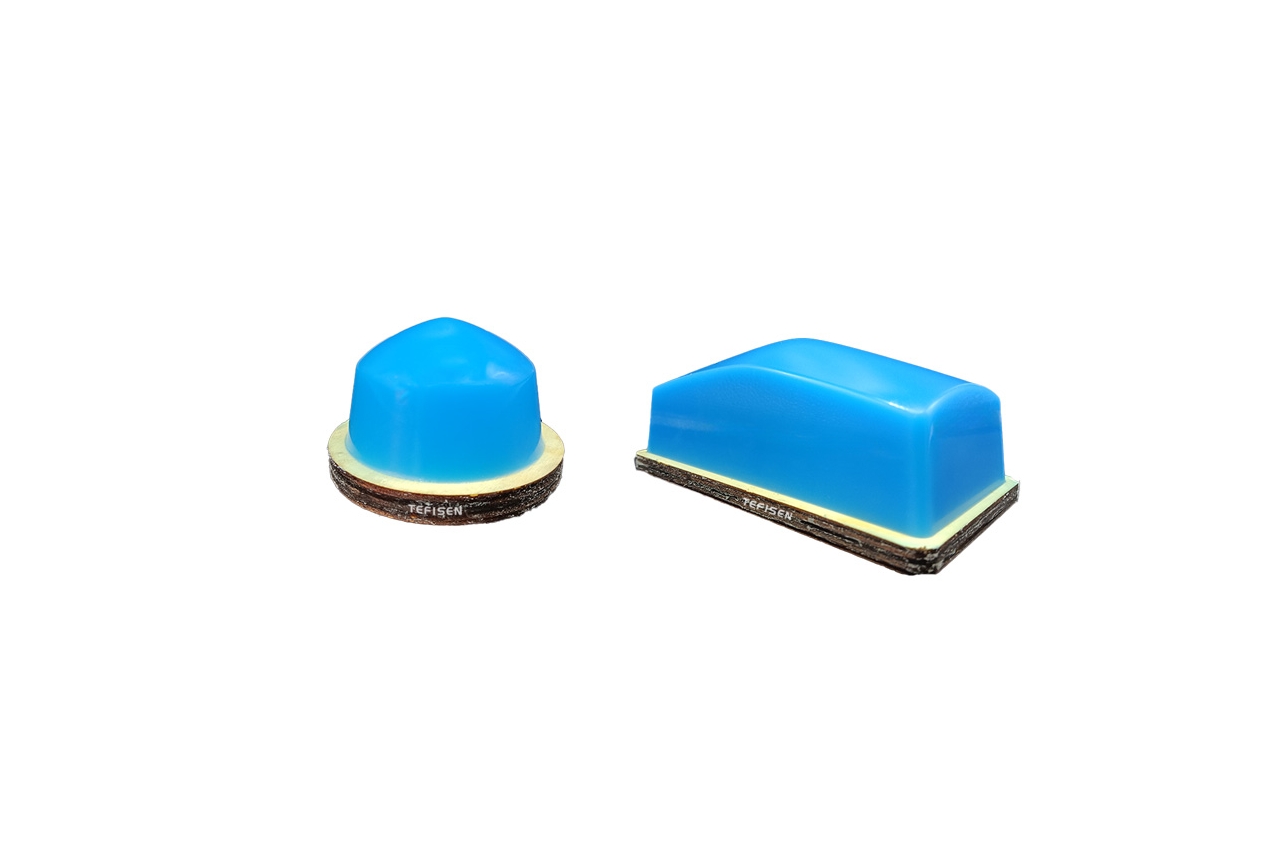

4.Square Pad Printing Pads

|

TS-F4223 |

TS-F3321 |

TS-F6139 |

|

|

|

|

52(L)X32(W) X35(H)mm |

43(L)X31(W) X33(H)mm |

71(L)X49(W) X34(H)mm |

5.Bar Pad Printing Pads

|

TS-29648 |

TS-31430 |

TS-12943 |

|

|

|

|

306(L)X58(W) X32(H)mm |

324(L)X40(W) X37(H)mm |

139(L)X53(W) X46(H)mm |

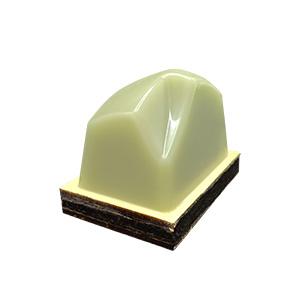

6.Special-Shaped Pad Printing Pads

|

TS-T3078 |

TS-T4069 |

TS-T2062 |

|

|

|

|

88(L)X26(W) X21(H)mm |

79(L)X71(W) X30(H)mm |

72(L)X34(W) X33(H)mm |

Generally speaking, pad printing pads may need to be adjusted to some extent based on different substrates, whether it's the size, hardness, or other factors. The most efficient approach is to customize the pad printing pads. (Why customize pad printing pads?) For more details, please contact us at +86-752-3296999 or sales@tefisen.com.

Over 1,000 kinds pad printing pads, full specifications and various shapes, including round pad printing pads, rectangular pad printing pads, round-cornered square pad printing pads, special (multi-point) pad printing pads, long strip (large) pad printing pads, etc. Customization is also supported.

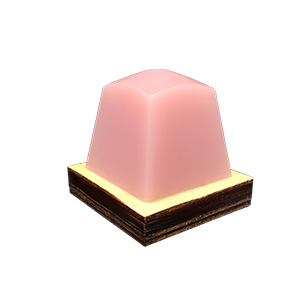

1. Additive pad printing pads

| Model No. | Color | Mixing ratio | Viscosity | Hardness | Tensile strength | Tear strength | Elongation at break |

| (mPa.s) | shore A | Mpa | KN/m | (%) | |||

| TF-6551 | Red | 10:1 | 75000 | 30 | 5.7 | 28 | 280 |

| TF-6777 | Green | 10:1 | 75000 | 32 | 5.7 | 28 | 250 |

| TF-6778 | Blue | 10:1 | 35000 | 19 | 4 | 12 | 400 |

2. Condensation type pad printing pads

| Model No. | Color | Mixing ratio | Viscosity | Hardness | Tensile strength | Elongation at break |

| (mPa.s) | shore A | Mpa | (%) | |||

| TF-8606 | White | 100:2 | 28000 | 25 | 3 | 15 |

| TF-8525 | Yellow | 100:2.5 | 32000 | 30 | 3 | 8 |

| TF-8266 | Red | 100:10 | 30000 | 27 | 3.5 | 24 |