New Hot Stamping Technology: TFS-200 Pneumatic Flatbed Hot Stamping Machine Solution

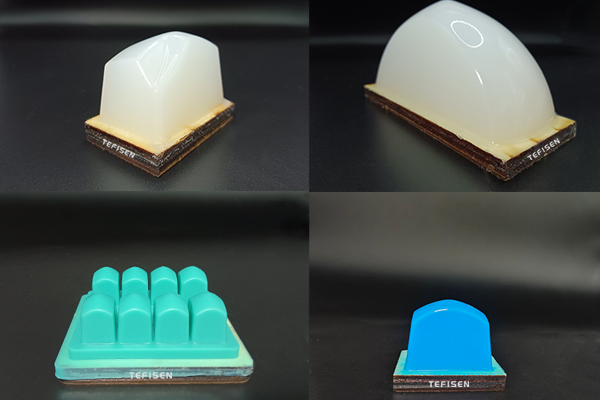

In packaging decoration, trademark nameplate production, and gift craftsmanship, hot stamping has always held a significant position due to its unique metallic luster and luxurious texture. The quality of the final hot-stamped effect largely depends on the performance and precision of the core equipment—the hot stamping machine. Designed specifically for small to medium-batch, high-precision stamping needs, the TEFISEN TFS-200 Pneumatic Flatbed Hot Stamping Machine integrates a robust mechanical structure, precise pneumatic control, and an intelligent temperature management system, embodying the technical sophistication of flatbed hot stamping. I. Features of the TEFISEN TFS-200 Pneumatic Flatbed Hot Stamping Machine The TEFISEN TFS-200 is designed for long-term stab...