Toy Pad Printing Technology: The Key to Unlocking New Market Doors!

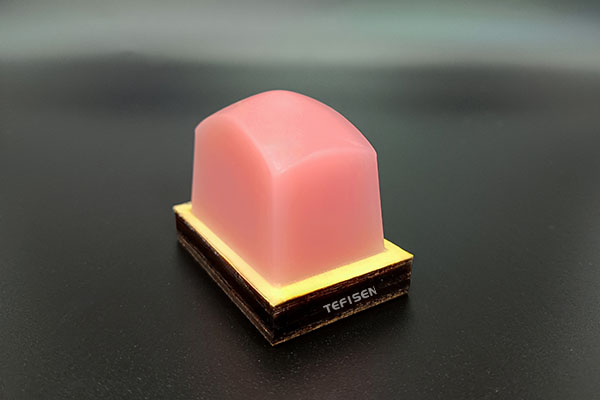

【Abstract】Pad printing technology plays a crucial role in toy manufacturing, enabling efficient printing of both simple logos and complex patterns. As demand for aesthetic appeal increases, it has become key in the industry. TEFISEN's single-color, two-color, and four-color machines meet diverse market needs, enhancing production efficiency. With increasing environmental standards, pad printing technology is poised for significant growth, offering a promising future for the toy industry. Let's take a closer look below! Toy pad printing technology is an indispensable core technology in toy manufacturing. Its main function is to provide high-quality surface printing for various toy products, from simple logos to complex patterns, all of which can be efficiently printed thro...