Screen Printing Machine Squeegees Selection Guide: Master It All in One Article

【Summary】In screen printing machine operations, the squeegee is a crucial tool & factors such as its hardness, blade shape, length, and thickness directly affect the printing results. So, how do we choose the right squeegee? What are the characteristics of different types of squeegees? What issues should we pay attention to when using a squeegee? This article mainly introduces the development history, material selection, selection criteria, characteristics, application, maintenance of screen printing machine squeegees.

I. Development History of Screen Printing Machine Squeegees

Screen printing machine squeegees, also known as scraper blades, can be traced back to the early 20th century. Initially used for ink transfer in silkscreen printing, with the continuous development of printing technology, the materials, designs, and functions of squeegees have also evolved. In the 1950s, with the rise of synthetic materials, manufacturers began using new materials such as polyurethane and silicone, significantly improving the wear resistance and printing effects of squeegees. In the 1990s, with the advancement of digital printing technology, the design of squeegees gradually became more precise and diverse to meet different printing needs.

In silkscreen printing, the squeegee is a vital tool that directly impacts the quality and effectiveness of the print.

II. Material Selection for Squeegees

The material selection of screen printing machine squeegees is crucial for print quality. Common materials include:

1. Rubber: Rubber squeegees have good elasticity and wear resistance, suitable for most printing processes. Their soft nature allows them to adapt to different substrate materials.

2. Polyurethane: Polyurethane squeegees offer higher wear resistance and chemical resistance, suitable for high-precision, high-demand printing tasks, especially when using special inks.

3. Silicone: Silicone squeegees are heat-resistant, suitable for special processes like thermal transfer printing.

Choosing the right squeegee material requires comprehensive consideration of the ink type, substrate material, and production environment.

III. Key Points for Selecting Squeegees

Choosing the right squeegee not only affects printing results but also production efficiency. Here are some important selection criteria:

1. Hardness: The hardness of squeegees is usually measured using the Shore hardness scale. The hardness selection depends on the complexity of the printed pattern and the characteristics of the substrate. Generally, harder squeegees are suitable for simple patterns, while moderately hard squeegees are needed for complex patterns.

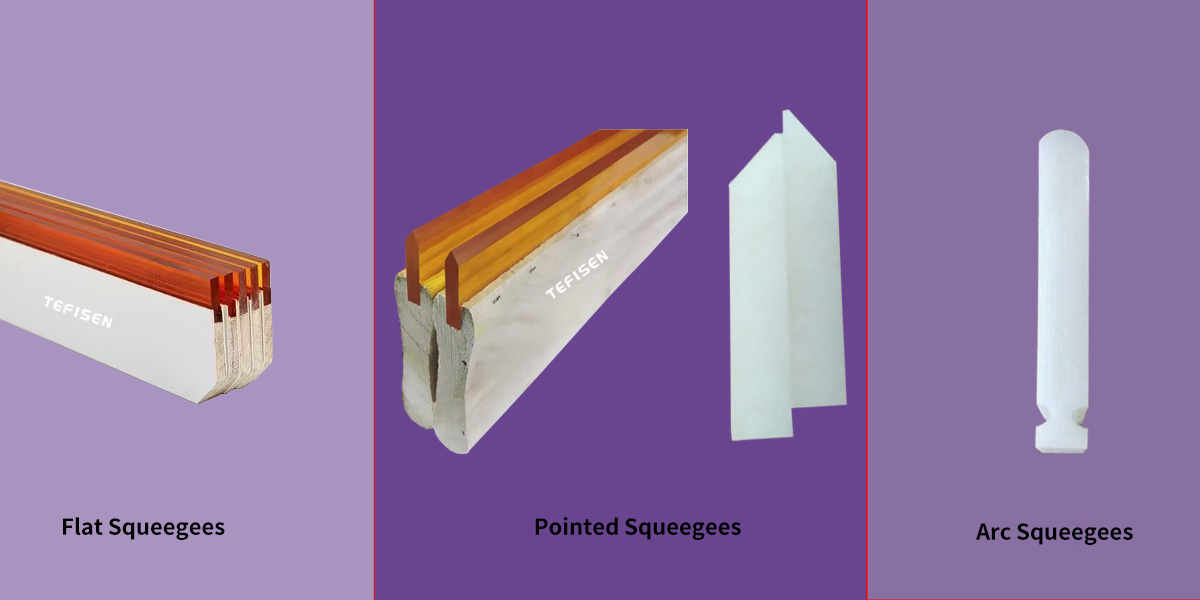

2. Blade Shape: The blade shape of squeegees also impacts printing results. Common blade shapes for screen printing machine squeegees include flat (square-corner), pointed (angled), and arc (R-corner), with different shapes suitable for different printing needs.

3. Length and Thickness: The length and thickness of squeegees must match the specifications of the screen printing machine squeegees. Being too long or too short will affect the uniformity and quality of printing.

IV. Flat Squeegee (Square-Corner Squeegee)

(A) Types and Characteristics

· Flat squeegees, also known as square-corner squeegees, have a right-angled blade. The corners of square-corner squeegees are powerful during operation, able to apply significant pressure to scrape ink across the screen, resulting in clearer and sharper lines in the printed pattern.

· Square-corner squeegees typically have a hardness range of Shore A60 to A80. This hardness gives square-corner squeegees good stability and wear resistance when printing on flat or hard surfaces.

(B) Application Scenarios

· Electronic Product Printing: When printing circuit boards, electronic component markings, and other electronic products, square-corner squeegees provide high-definition lines and precise patterns. For example, when printing circuit board patterns with a line width of 0.5mm, square-corner squeegees can control line deviation within ±0.05mm, ensuring stable print quality.

· Metal Product Printing: For printing on metal surfaces, such as stainless-steel signs and aluminum alloy panels, square-corner squeegees can apply significant pressure to firmly adhere the ink to the metal surface. Statistically, about 70% of enterprises choose square-corner squeegees for metal product printing.

(C) Requirements

· Angle Adjustment: The usage angle of square-corner squeegees is generally between 60° and 75°. In practical applications, adjustments should be made based on factors such as ink viscosity, screen mesh count, and printing speed. For example, when using high-viscosity ink and fine mesh screens, the angle can be increased to improve ink permeability.

· Pressure Control: The printing pressure of square-corner squeegees should be moderate. Excessive pressure can cause screen deformation and excessive ink thickness, affecting print quality; insufficient pressure will result in insufficient ink permeation and unclear patterns. Generally, a printing pressure between 2 and 5 kg/cm² is suitable. For example, when printing an ink layer with a thickness of 0.1mm, the pressure can be controlled around 3 kg/cm².

V. Pointed Squeegee (Angled Squeegee)

(A) Types and Characteristics

· Pointed squeegees, also known as angled squeegees, have a sharp-angled tip, with shapes like a V, single-sided bevel, etc. This design allows pointed squeegees to more flexibly adapt to uneven substrate surfaces, sweeping ink across the screen rather than scraping it like square-corner squeegees.

· Pointed squeegees have a relatively lower hardness, typically in the range of Shore A40 to A60. Lower hardness enables pointed squeegees to better print patterns without damaging the substrate surface.

(B) Application Scenarios

· Prints with Surface Defects: When the surface of prints has convex and concave defects, pointed squeegees can effectively adapt to this situation and print the pattern completely. For example, when printing on wooden furniture surfaces, due to wood grain and knots, square-corner squeegees may result in incomplete printed patterns, while pointed squeegees can effectively solve this problem.

· Printing Needs with Thin Ink: Pointed squeegees scrape thinner ink layers, suitable for printing scenarios requiring thin coatings. For example, when printing screen protectors for mobile phones and optical lenses, thinner ink layers are needed to avoid affecting product performance and appearance. In these fields, pointed squeegees have a utilization rate of about 60%.

· Roll Printing Applications: Pointed squeegees are used extensively in roll printing as they can make good contact with the roller surface, uniformly transferring ink to the roller, and then transferring the ink to the substrate. For example, when printing continuous plastic films, pointed squeegees can maintain stable print quality during high-speed roll printing.

(C) Requirements

· Tip Angle Selection: The tip angle of pointed squeegees is generally between 30° and 45°. Different angles are suitable for different printing needs. Smaller angles can scrape thinner ink layers, while larger angles can improve ink permeability. For example, when printing an ink layer with a thickness of 0.05mm, a 30° tip angle can be selected.

· Ink Scraping Speed Control: The ink scraping speed of pointed squeegees should be adjusted based on the drying speed of the ink and printing quality requirements. Generally, an ink scraping speed between 5 and 10 m/min is suitable. For example, when using fast-drying ink, the scraping speed can be appropriately increased to avoid ink drying on the screen and affecting print quality.

VI. Arc Squeegee (R-Angle Squeegee)

(A) Types and Characteristics

· An arc squeegee, also known as an R-angle squeegee, features an arcuate squeegee edge resembling the shape of the letter "R". This design allows the R-angle squeegee to provide a larger contact area and pressure during printing, resulting in a thicker ink deposit.

· Arc squeegees are relatively hard, typically ranging from Shore A70 to A90 on the hardness scale. Their high hardness enables them to withstand significant pressure, making them suitable for printing scenarios requiring thick ink layers.

(B) Application Scenarios

· Three-Dimensional Printing: In three-dimensional printing, achieving a three-dimensional effect requires printing ink layers of different thicknesses. The arc squeegee can deposit thicker ink layers, providing the necessary conditions for three-dimensional printing.

· Relief Printing: Relief printing is a technique that achieves a relief effect through thick ink layers. The arc squeegee is suitable for relief printing, enhancing the three-dimensional and layered appearance of the patterns. For example, when printing artistic decorations, the arc squeegee can deposit ink layers ranging from 0.8 to 1.2mm in thickness, making the relief effect more prominent.

· Special Effect Printing: Besides three-dimensional and relief printing, the arc squeegee is also suitable for other special effect printing needs. For instance, when printing products that require emphasized pattern textures or increased abrasion resistance, the arc squeegee can deposit thicker ink layers to meet these specific printing requirements.

(C) Requirements

· Pressure Adjustment: The printing pressure of the arc squeegee is relatively high, generally ranging from 5 to 10kg/cm². In practical applications, adjustments are necessary based on factors such as ink viscosity, substrate material, and printing effect requirements. For example, when printing on soft plastic materials, the pressure can be appropriately reduced to avoid substrate deformation.

· Blade Angle Control: The blade angle of the arc squeegee is typically between 45° and 60°. Compared to square-angle and pointed squeegees, the angle of the arc squeegee is smaller to better accommodate its arcuate edge, improving ink permeability and printing quality. For example, when printing an ink layer of 0.8mm thickness, the angle can be controlled around 50°.

VII. Maintenance and Care of Squeegees

Regular maintenance and care are essential to ensure the service life and printing quality of screen printing machine squeegees. Here are several maintenance tips:

1. Cleaning: After each printing session, immediately clean the squeegee to avoid damage caused by ink residue. It is recommended to use a dedicated cleaning agent for cleaning.

2. Wear Inspection: Regularly inspect the squeegee for wear, such as cracks or deformation, and replace it promptly if any issues are found.

3. Storage Conditions: Store squeegees in a dry, cool environment, avoiding direct sunlight and high temperatures to prevent material aging.

VIII. Conclusion

The three types of screen printing machine squeegees—flat squeegees (square-angle), pointed squeegees (oblique), and arc squeegees (R-angle)—each have their unique characteristics and application scenarios. Square-angle squeegees are suitable for printing on flat or hard surfaces, producing clear lines; oblique squeegees are suitable for printing on surfaces with defects and require thinner ink layers, commonly used in roll printing; and arc squeegees deposit thicker ink, making them suitable for three-dimensional printing, relief printing, and special effect printing. When selecting a squeegee, comprehensive consideration should be given to specific printing requirements and substrate characteristics, with precise adjustments made based on numerical data to ensure optimal printing results. Additionally, during the use of squeegees, attention should be paid to their maintenance and care, with regular cleaning and replacement to extend their service life and improve the stability and reliability of printing quality.