How Pad Printing Technique Fuels the Multi-Billion Dollar Holiday Economy

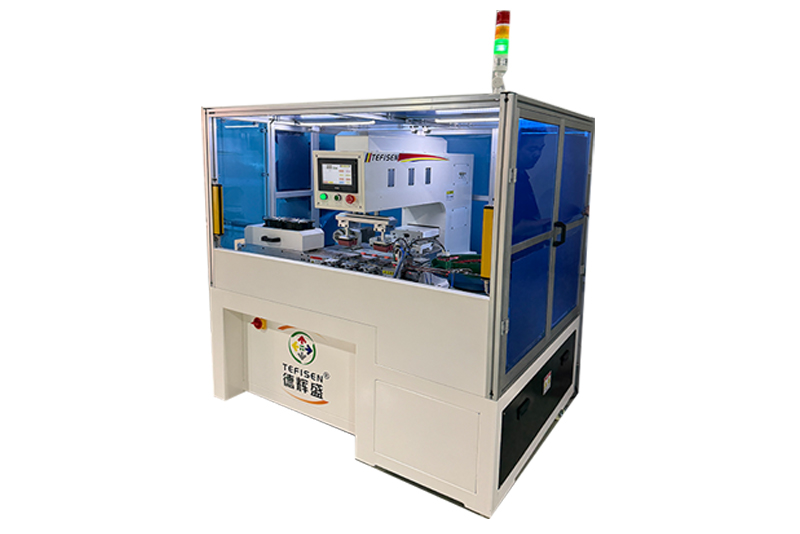

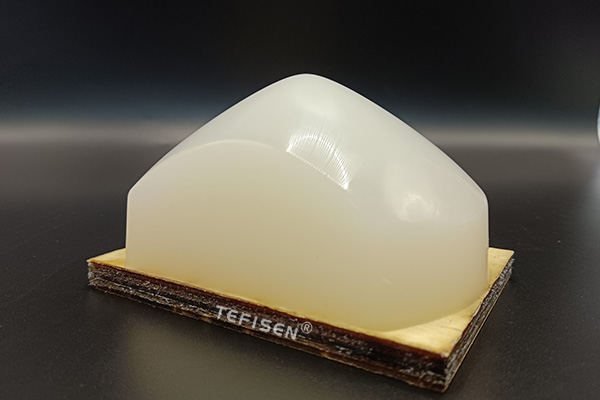

“#The Whole World Knows China is on Holiday” When the prediction of "2.36 billion inter-regional trips" flooded social media feeds, and when the human tides on the Great Wall, the lantern reflections of West Lake, and the Tang Dynasty fervor in Xi'an were broadcast globally, we witnessed not just a nationwide celebration, but a vivid manifestation of the robust pulse of China's holiday economy. Foreign media outlets keenly captured this phenomenon, interpreting it as a key signal of recovering consumer confidence and burgeoning market vitality. Yet, beneath this massive wave of consumption, an invisible "machine" is operating at an unprecedented pace, precisely "printing" festive joy, cultural symbols, and brand warmth onto every corner of the holiday—this is the pad printing machine....