Efficient Pad Printing Solution for VR Glass Frames | TFS-P1-125

With the rapid development of virtual reality (VR) technology, VR glasses, as a key hardware component, have been increasingly drawing market attention. The frame of VR glasses, being one of its important parts, often requires precise pad printing for clear gear markings and to enhance the user experience. This article is based on the TFS-P1-125 pad printing machine, combining a practical case study to analyze how to achieve high-quality pad printing on VR glasses frames. It also explores market demand and our company's pre-sales and after-sales services.

I. Customer Requirements and Printing Standards

The customer requires the printing of gear numbers (e.g., 0, 1, 2, 3, etc.) on the edge of the VR glasses. The printing effect must withstand wear tests involving cosmetics and alcohol, as well as pass cross-hatch adhesion tests and boiling tests. These requirements ensure the durability and long-term stability of the markings, especially in high-usage environments and under various conditions.

II. Pad Printing VR Glasses

1. Equipment and Material Overview

1.1 Pad Printing Machine: TFS-P1-125

- Model: TFS-P1-125

- Standard plate size: 100mm x 100mm

- Printing area: 50mm x 50mm

- Printing speed: 1,800 pcs/hour

- Object height: 70mm

The TFS-P1-125 is an efficient pad printing machine equipped with advanced technical parameters. Its standard plate size is 100mm x 100mm, suitable for larger-sized prints and capable of supporting a printing area up to 50mm x 50mm. With a printing speed of 1,800 pieces per hour, it is ideal for mass production, meeting the demands for high-speed manufacturing. Its object height of 70mm ensures it can handle frames of various sizes, guaranteeing accurate coverage and printing precision.

1.2 Pad Printing Pad: TFS-Y5220

- Shape: Round

- Hardness range: 20 to 31 Shore A

The TFS-Y5220 pad has a round design, suitable for printing on curved or edge surfaces. Its hardness range of 20 to 31 Shore A provides flexibility, allowing the selection of appropriate hardness based on the printing requirements. Softer pads are suitable for finer prints, while harder pads work well for harder materials and more demanding printing tasks.

1.3 Ink: TS-200 Series Grey

The TS-200 series grey ink has excellent adhesion and durability, making it ideal for printing on VR glasses frames. Its properties ensure that the printed design remains stable over long periods, resistant to fading or peeling, and capable of passing wear tests involving cosmetics and alcohol.

2. Printing Process Analysis

2.1. Equipment Setup and Preparation

Before actual printing, proper setup and preparation are critical:

- Equipment inspection: Ensure all functions of the TFS-P1-125 are working correctly, especially pressure adjustment, speed settings, and pad installation.

- Pad selection: Choose the appropriate hardness of the TFS-Y5220 pad based on the frame's material and shape. Typically, a hardness between 20 to 31 Shore A is selected to ensure image clarity and stability.

- Plate design: Engrave the gear number pattern on a 100mm x 100mm standard plate, ensuring the pattern size and position match the 50mm x 50mm printing area.

2.2. Printing Settings

- Printing speed: Set at 1,800 pieces per hour to ensure efficient production.

- Printing pressure: Adjust to an appropriate level to ensure the ink is evenly transferred onto the VR glasses frame.

- Pad selection: Choose a pad with appropriate hardness according to the requirements, ensuring clear and durable prints.

2.3. Operation

Start the TFS-P1-125 pad printing machine and begin the printing process. Each VR glasses frame is moved through the equipment, and the ink is transferred to the frame via the pad. Monitor the printing process to ensure that the gear numbers (0, 1, 2, 3, etc.) on each frame are clearly visible without any blurring or misalignment.

2.4. Quality Control

- Cosmetics and alcohol wear test: Perform a 200-cycle wipe test to ensure the printed design can resist the effects of cosmetics and alcohol, maintaining strong adhesion and clarity.

- Cross-hatch test: Check the adhesion and wear resistance of the ink to ensure the design does not peel easily over time.

- Boiling test: Conduct a boiling test to verify the durability and stability of the printed design under high temperatures.

Table 1: Printing Quality Test Results

| Test Item | Result | Description |

| Cosmetics Wear Test | Pass | No noticeable fading after 200-cycle wiping |

| Alcohol Wear Test | Pass | Design remains clear after alcohol wiping |

| Cross-Hatch Test | Pass | Ink adhesion is good, design does not easily peel off |

| Boiling Test | Pass | Design remains stable under high temperatures without fading |

III. Market Demand Analysis

1. Market Size and Growth

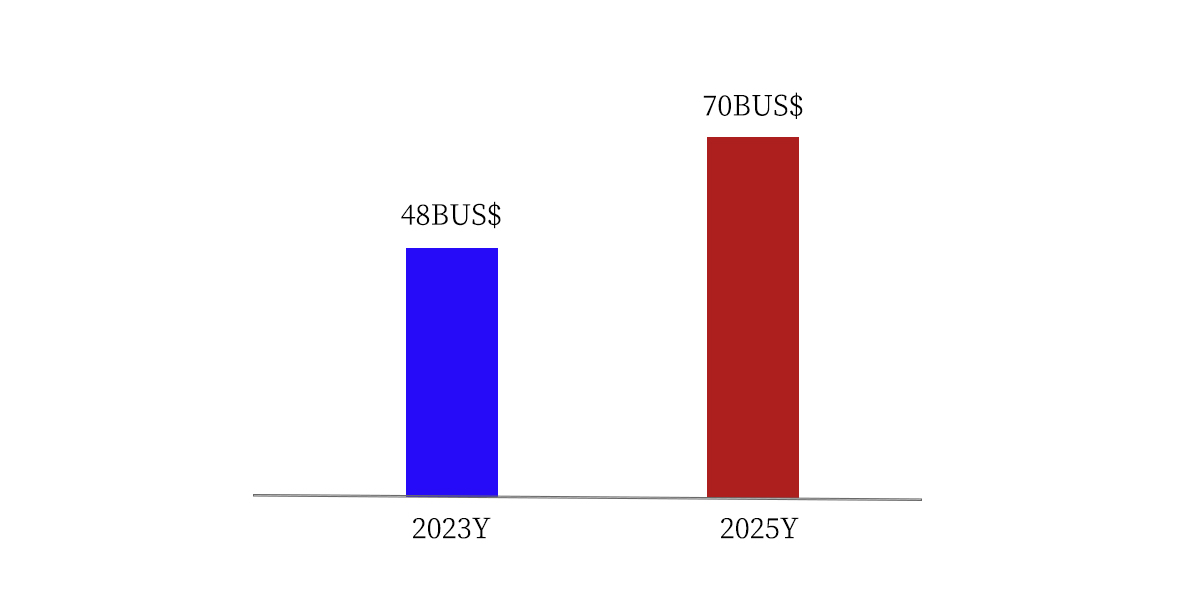

Based on market analysis, the worldwide VR industry was valued at around $48 billion in 2023 and is projected to expand to $70 billion by 2025, reflecting an annual growth rate exceeding 10%. This growth is mainly driven by the widespread use of VR technology in gaming, education, healthcare, and other sectors. As consumer demand for a better VR experience continues to rise, the market for high-quality and durable VR glasses accessories, including frame markings, is also expanding.

2. User Demand

Users have specific requirements for the frame markings on VR glasses, including clear numeric displays, wear resistance, and resistance to chemical corrosion. Printing quality directly affects the user experience and the product’s market competitiveness. Therefore, using advanced pad printing technology and high-quality materials can meet these high standards, adding value to the product and increasing market appeal.

IV. Pre-Sales and After-Sales Service

1. Pre-Sales Service

- Solution design: We provide free customized solution design services to help customers choose the most suitable printing solution, ensuring their specific needs are met.

- Technical consultation: Free professional technical consultation is provided to ensure that the equipment selected by the customer fully meets their actual needs.

2. After-Sales Service

- Equipment installation and debugging: Free installation and debugging services are provided to ensure the equipment operates normally.

- Operation and maintenance training: We offer training in technical operation and equipment maintenance to ensure customers can proficiently use and maintain the equipment.

- Lifetime maintenance and support: From the date of purchase, customers enjoy lifetime maintenance and technical support for the equipment.

- Engineer consultation service: Engineers provide free lifetime consultation and guidance.

- Quick response support: We offer a four-hour response service and guarantee technical support within 24 hours.

V. Conclusion

By using the TFS-P1-125 pad printing machine, TFS-Y5220 pad, and TS-200 series grey ink, along with meticulous operation and strict quality control, high-quality gear number printing on VR glasses frames can be achieved, meeting the market's demands for clarity and durability. In addition, our comprehensive pre-sales and after-sales services ensure that customers receive full support and assurance throughout the equipment usage process. This all-around service and advanced technical support will help customers achieve efficient and precise production goals, improving product quality and market competitiveness.