AI-Powered Tefisen: A New Leap in Fully Automatic Screen Printing Machines

Fully automatic screen printing machines play a significant role in the printing industry. With continuous technological advancements globally, the development trends and market applications of screen printing machines are increasingly characterized by greater intelligence and automation. This article explores the latest global technologies in fully automatic screen printing machines, their applications, the integration of artificial intelligence (AI), and future market growth predictions.

I. Technological Development Trends of Fully Automatic Screen Printing Machines

1. Precision Control and Efficient Production

As global manufacturing demands for high precision and efficiency continue to rise, the technology of fully automatic screen printing machines is evolving accordingly. The latest generation of fully automatic screen printing machines features high-precision servo systems and intelligent positioning technology, allowing for more detailed control to meet the demands of high-precision printing. Modern screen printing machines can achieve a precision of ±0.02 millimeters, with some models producing up to 1200 pieces per hour.

Data Support: The latest fully automatic screen printing machines released in 2023 have a precision of ±0.02 millimeters, approximately a 50% improvement over earlier models; production speed has increased by 30%, with an hourly output of up to 1200 pieces.

2. Modular Design and Multifunctionality

The global trend in the design of fully automatic screen printing machines is moving towards modularity and multifunctionality. Equipment can be customized and expanded according to specific needs, such as integrating UV curing modules, hot stamping modules, and automatic feeding modules to accommodate different printing tasks. This modular design not only enhances the flexibility of the equipment but also significantly improves the overall production efficiency of the production line.

Case: In the packaging industry, by integrating UV curing and hot stamping modules, fully automatic screen printing machines can simultaneously complete pattern printing and surface processing, improving production efficiency by approximately 40%.

3. Application of Green and Environmentally Friendly Technologies

As environmental regulations become increasingly stringent, the screen printing industry is also moving towards greener production practices. Fully automatic screen printing machines now use low-energy drive systems and eco-friendly inks, such as water-based inks, to reduce the emission of harmful substances. During the printing process, the energy consumption of these machines has decreased by 20%-30% compared to traditional models, and waste ink production has been reduced.

Environmental Data: The latest fully automatic screen printing machines in the global market consume 25% less energy compared to traditional equipment and can reduce carbon dioxide emissions by approximately 10 tons annually.

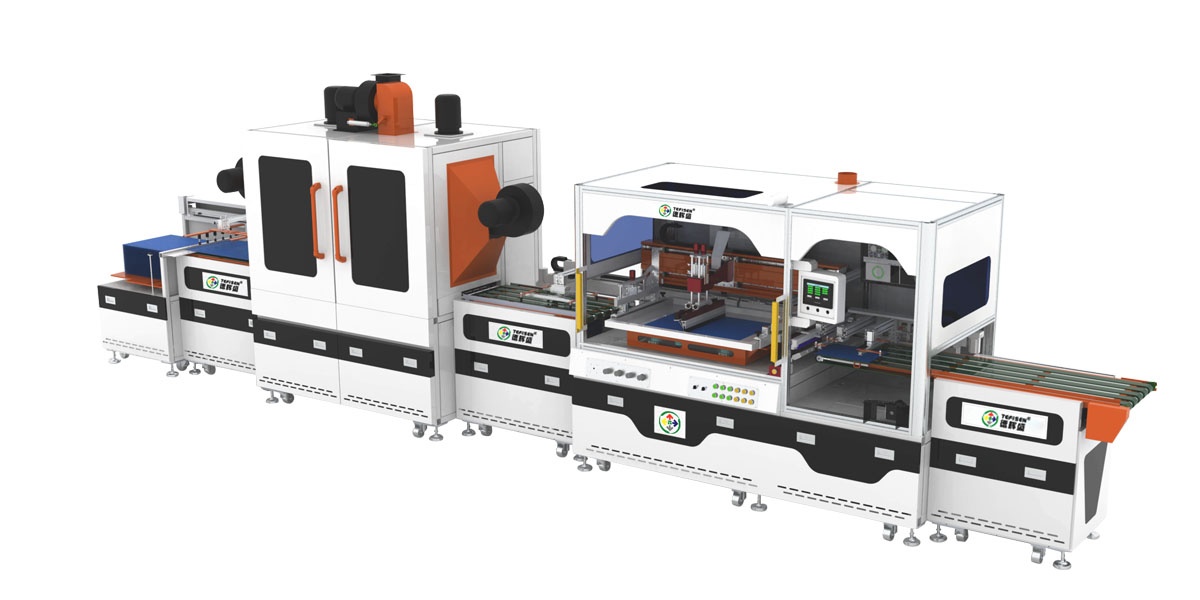

4. Tefisen Fully Automatic Screen Printing Machine Technology

The Tefisen TFS-AS668F latest fully automatic screen printing machine features an advanced precision servo control system, achieving high-precision printing with an error margin of ±0.02mm. Its core consists of a CNC system for precise positioning and speed control of mechanical components, greatly enhancing printing quality. Additionally, this intelligent control system allows for fully automatic operation, reducing the need for human intervention and significantly increasing production efficiency.

Technical Parameters:

- • Precision: ±0.02mm

- • Maximum Printing Speed: 1000 pieces/hour

- • Operating Interface: Full-touchscreen intelligent control

- • CCD Alignment System

- • Robotic Automatic Loading and Unloading

The Tefisen TFS-AS668F seamlessly integrates with fully automated production lines and, when equipped with our high-efficiency energy-saving drying oven, the machine can automatically sense and stack printed pieces, with an alarm notification for a stack height of 230mm, reducing the need for manual inspection and further simplifying the production process.

II. Application Areas of Fully Automatic Screen Printing Machines

1. Electronics Industry

The electronics industry relies heavily on fully automatic screen printing machines for printing on electronic product housings, screens, and small electronic components. High-precision fully automatic screen printing machines can handle complex geometries, ensuring clarity and consistency of patterns. For example, logo printing on mobile phone housings demands high precision, and screen printing machines excel in these applications.

Data Support: The proportion of fully automatic screen printing machines used in the electronics industry grows annually by approximately 8%, with over 60% of electronic product housings relying on fully automatic screen printing machines in 2023.

2. Automotive Components Industry

The automotive manufacturing industry has high requirements for printing quality and durability. Fully automatic screen printing machines provide excellent precision and wear resistance for printing on dashboard components, buttons, and other parts, while also enabling large-scale production within a short timeframe. The demand for screen printing machines in the automotive industry continues to grow, especially with trends in new materials and personalized designs.

Market Demand: By 2025, the proportion of fully automatic screen printing machines used in the global automotive industry is expected to reach 15%, with a compound annual growth rate (CAGR) of 6%.

3. Packaging Industry

In the packaging industry, particularly for cosmetics, food, and beverage products, the demand for personalized packaging is rapidly growing. Fully automatic screen printing machines, with their fast and precise printing capabilities, are widely used for pattern printing on such packaging. By combining advanced technologies like UV printing, fully automatic screen printing machines can quickly achieve high-quality prints.

Case Analysis: A cosmetics company achieved batch customization of 500,000 products with a fully automatic screen printing machine, reducing the delivery cycle by 30%.

III. AI Technology in Fully Automatic Screen Printing Machines

1. AI Optimization of Production Parameters

The introduction of AI technology enables fully automatic screen printing machines to automatically optimize parameters such as pressure, ink thickness, and speed based on real-time production data, ensuring that each batch achieves optimal print quality. This intelligent control reduces human operational errors and effectively saves production time.

Data Analysis: Through AI technology, a company improved production efficiency by 15% and reduced waste rate by 10%.

2. Fault Prediction and Autonomous Maintenance

AI can monitor the operational status of fully automatic screen printing machines, analyze equipment data in real-time, and predict faults before they occur. This predictive maintenance reduces equipment downtime and maintenance costs. The latest fully automatic screen printing machines with AI autonomous maintenance functionality have seen a 20% decrease in fault rates.

Data Support: A large manufacturing enterprise reduced annual maintenance costs by approximately 15% using AI fault prediction systems.

3. Real-Time Data Monitoring and Intelligent Decision-Making

AI systems can also analyze data from the production process in real-time, providing intelligent decision-making support. For example, AI can dynamically adjust production plans based on market demand, optimize raw material usage, and reduce inventory backlog. This flexible production management mode effectively responds to market fluctuations.

Table 1: Effects of AI Technology on Fully Automatic Screen Printing Machines

| Application Function | AI Optimized Effect | Non-AI Effect |

|---|---|---|

| Production Efficiency Improvement | 15% | 5% |

| Waste Rate Reduction | 10% | 20% |

| Downtime Reduction | 25% | 10% |

| Fault Prediction Accuracy | 85% | None |

IV. Market Growth Forecast for Fully Automatic Screen Printing Machines

1. Global Market Growth

According to market research data, the global market for fully automatic screen printing machines is expected to grow at a compound annual growth rate (CAGR) of 6.5% from 2023 to 2028. This growth is driven by the high-precision printing demands of industries such as electronics, automotive, and packaging. Particularly in the Asia-Pacific region (e.g., China, Japan, and South Korea), market demand continues to grow, with the global market size expected to reach $4 billion by 2028.

Global Market Growth Forecast: The market size was $2.8 billion in 2023, and it is projected to reach $4 billion by 2028, with a CAGR of 6.5%.

2. Regional Market Analysis

The Asia-Pacific region dominates the global fully automatic screen printing machine market, with significant market opportunities driven by the growth of manufacturing industries in China and India. Demand in Europe and North America is concentrated on high-end equipment and intelligent production lines.

China Market Growth Forecast: By 2028, the CAGR for the Chinese market is expected to reach 8%, with the market size exceeding $1.5 billion.

3. Industry Market Forecast

- • Electronics Industry: With the growing demand for smart devices and wearables, the electronics industry's demand for fully automatic screen printing machines is expected to grow at a CAGR of 7%.

- • Automotive Industry: The printing demand for new energy vehicle components is significantly increasing, with a forecasted CAGR of 6.2%.

Table 2: Global Market Growth Forecast for Fully Automatic Screen Printing Machines

| Year | Global Market Size (Billion USD) | CAGR |

|---|---|---|

| 2023 | 2.8 | 6.5% |

| 2025 | 3.3 | 6.5% |

| 2028 | 4.0 | 6.5% |

V. Conclusion

Technological advancements in fully automatic screen printing machines provide efficient and precise printing solutions across various industries. As AI technology becomes more integrated, the level of intelligence in screen printing machines significantly increases, further enhancing production efficiency and print quality. In the coming years, the demand from the electronics, automotive, and packaging industries will continue to drive the rapid growth of the fully automatic screen printing machine market, with substantial potential in the Asia-Pacific region.

Combined with AI technology, fully automatic screen printing machines are set to become crucial equipment in the future manufacturing industry, propelling the global printing sector towards a more intelligent and environmentally friendly future.