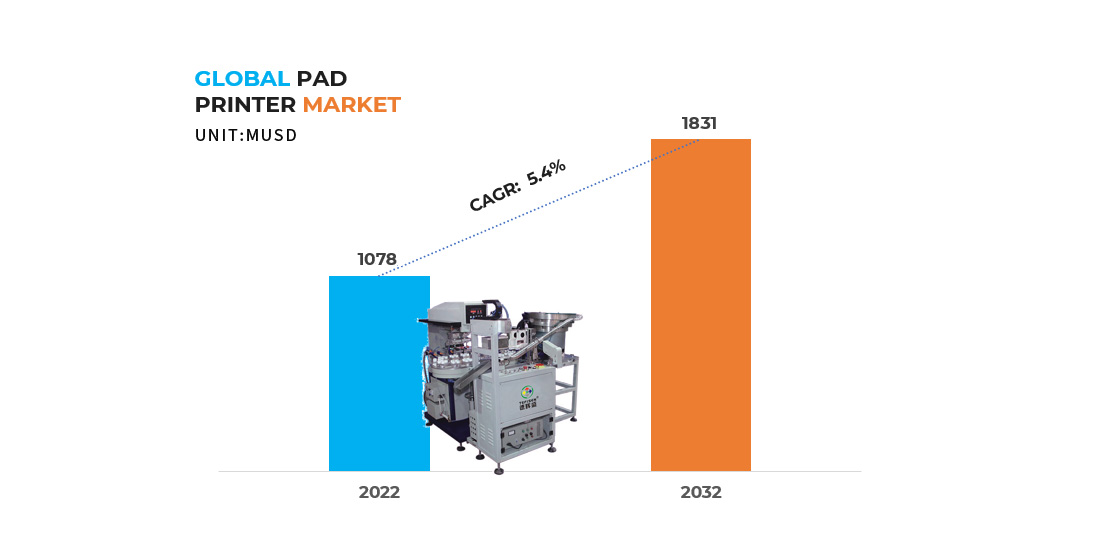

By 2032, The Market For Fully Automated Pad Printing Machines Is Forecasted To Hit $1.83B.

I. Concept and Characteristics of Fully Automatic Pad Printing Machine

A fully automatic pad printing machine is a highly automated printing equipment that integrates mechanical, electronic, and pneumatic technologies to achieve a fully automated printing process from pattern etching to ink transfer onto object surfaces. This equipment plays a pivotal role in the printing industry, catering to diverse and complex surface printing requirements with its efficiency, precision, and flexibility.

Importance and Characteristics of Pad Printing Technology:

Pad printing, as an indirect printing technology utilizing concave rubber heads, boasts the following notable features:

- High Precision: Capable of producing extremely fine lines, fonts, and patterns, meeting the demands of high-precision printing.

- Versatility: Applicable to a wide range of material surfaces, including plastics, toys, glass, metals, ceramics, electronics, IC packaging, etc. It excels in printing on small areas, concave and convex surfaces that are challenging to address with other methods.

- Efficiency: Fully automated pad printing machines significantly enhance printing efficiency through automated control, thereby reducing labor costs.

The extensive application of pad printing technology in these domains underscores its indispensability in modern industrial production.

II. Overview of Fully Automatic Pad Printing Machine

1. Definition and Classification:

Definition: A fully automatic pad printing machine is a printing equipment integrating mechanical, electronic, and pneumatic technologies, achieving precise pattern printing through automated control.

Classification:

- By Printing Colors: Monochrome, dual-color, four-color, six-color, and more, catering to varying degrees of complexity and fineness in printing requirements.

- By Automation Level: Turntable and robotic types. Turntable machines utilize rotating disks for automatic workpiece positioning and printing, while robotic models harness the flexibility and precision of robotic arms for more intricate printing tasks.

2. Working Principle:

The fully automatic pad printing machine operates based on the indirect concave rubber head printing principle of pad printing technology. The specific steps include:

- Pattern Etching: Initially, the pattern is accurately etched onto a polished steel plate, creating a pattern etching plate.

- Ink Transfer:

- As the pad moves forward, an inking roller fills the etched pattern on the plate with ink.

- When the pad retracts, a squeegee blade removes excess ink from the plate, leaving only the ink in the etched pattern.

- Subsequently, a soft rubber pad picks up the ink from the etched pattern and transfers it to the object to be printed.

- Printing onto the Object: Through precise control of the pad's position and pressure, the inked pattern is accurately printed onto the object's surface.

In a fully automatic pad printing machine, this process is automated through the collaborative work of mechanical, electronic, and pneumatic components. For instance, servo motors drive the precise movement of the pad; sensors detect workpiece positions and statuses; and PLCs (Programmable Logic Controllers) manage the logic and timing of the entire printing process. The precise coordination of these components ensures the machine's efficient, stable, and precise operation.

III. Core Components of Fully Automatic Pad Printing Machine

The core section of the printing system in a fully automatic pad printing machine comprises servo motors and their control systems, etching plates and pattern etching technology, ink supply systems, silicone pad printing heads, and their motion mechanisms, all contributing to ensuring the quality and efficiency of printed products.

-

Servo Motors and Control Systems:

They play a pivotal role in fully automatic pad printing machines, responsible for precisely controlling various movements, including the lifting, forward/backward movement, and rotation of the pad printing head, to ensure printing accuracy and stability. Servo motors are characterized by high precision, fast response speed, and high torque, meeting the exacting position and speed control requirements during the printing process. -

Etching Plates and Pattern Etching Technology:

Etching plates serve as the crucial component for carrying patterns, with the desired graphic information etched onto their surfaces through chemical or physical methods. -

Ink Supply System:

This system includes fixed ink pans, movable ink pans, or ink cups, providing stable and uniform ink supply for the printing process. -

Silicone Pad Printing Heads:

As the key executing component of the printing system, silicone pad printing heads excel in ink absorption and transfer, precisely depositing ink from the etching plate onto the surface of the object to be printed. -

Motion Mechanisms:

Comprising guide rails, sliders, cylinders, and other components, these mechanisms drive the precise movements of silicone pad printing heads, etching plates, and other parts, enabling efficient printing operations.

IV. Global Pad Printing Machine Market Analysis

According to Emergen Research, the global pad printing machine market was valued at USD 1.078 billion in 2022 and is projected to reach USD 1.831 billion by 2032, growing at a CAGR of 5.4%.

1. Widespread Application in Electronics Industry:

Printing processes are crucial in the electronics industry for feature identification, essential for quality assurance and regulatory compliance. Fully automatic pad printing machines are widely used in this sector, designed to handle small and delicate components while delivering high-precision, quality patterns.

2. Medical and Healthcare Sector Dominates Revenue Share:

Medical devices require consistent and repeatable marking, which is often more cost-effective with specialized pad printing. Applications include test tubes, catheters, shafts, clips, syringe handles, adapters, housings, and connectors.

3. Surging Demand from New Energy Vehicles:

Canalys predicts that the global new energy vehicle market will grow by 27% in 2024, reaching 17.5 million units. Major markets like China, the US, and Europe will witness increased sales of new vehicles. The automotive industry is increasingly adopting pad printing due to its ease of use, simplicity, and efficiency.

4. North America Leads in Revenue Share:

This is primarily attributed to the continuous development of companies like Inkcups. In January 2022, MPE Partners, a private equity firm based in Boston, Massachusetts, and Cleveland, Ohio, invested in Inkcups, a printing industry leader, to accelerate its five-year growth strategy and expand into new markets and areas. This investment will also fund further development of Inkcups' printing systems and consumables, strengthening its global sales and customer service network.

In conclusion, fully automatic pad printing machines play an irreplaceable role in the printing industry due to their exceptional performance and broad application areas. With continuous technological advancements and evolving market demands, these machines will continue to evolve and improve, providing superior and efficient solutions for printing needs across various industries.