Comprehensive Guide to Pad Printing Machine Pads: Types, Materials, and Applications

Pad Printing Machine Pads Introduction

Pad printing machine pads, often referred to simply as "pads," are essential components in the pad printing process. These pads are responsible for transferring ink from the etched plate (cliché) to the substrate. The quality of the pad greatly influences the printing results, making it a critical element in achieving high-quality prints. This article delves into the different types of pads, their materials, manufacturing processes, usage, maintenance, and key considerations when selecting the right pad for your needs.

Types of Pad Printing Machine Pads

By Shape

o Round Pads: The most common type, round pads are versatile and suitable for a wide range of printing applications. Their design ensures even ink pick-up and transfer.

o Oval Pads: Ideal for elongated or oval-shaped designs, these pads cover larger areas more efficiently.

o Pointed Pads: Perfect for intricate and fine detail printing, pointed pads allow for precise transfer of detailed graphics.

o Flat Pads: Used for flat or slightly curved surfaces, flat pads are suitable for large, even designs.

By Hardness

o Soft Pads (Shore Hardness 20-30A): Best for uneven or highly contoured surfaces, as their softness allows them to conform to irregular shapes.

o Medium Hardness Pads (Shore Hardness 30-50A): Versatile and suitable for most printing needs, offering a good balance between flexibility and stability.

o Hard Pads (Shore Hardness 50-70A): Ideal for smooth, flat surfaces where precision and sharpness are critical.

Materials and Manufacturing Processes

Materials

Pads are typically made from silicone rubber due to its excellent elasticity, durability, and resistance to various chemicals. The composition of silicone rubber can be adjusted to alter its hardness, elasticity, and surface finish to meet specific printing requirements. The global demand for silicone rubber in pad printing applications grows at an approximate rate of 4.5% annually.

Manufacturing Process

1. Mold Creation:

o Time Required: 10-15 hours

o Custom molds are designed based on the desired pad shape and specifications, typically using metal or high-strength plastic.

2. Silicone Rubber Mixing:

o Time Required: 30 minutes per batch

o Silicone rubber is mixed with catalysts and other additives to achieve the required properties.

3. Injection Molding:

o Time Required: 2-3 hours

o The prepared silicone mixture is injected into molds and subjected to heat and pressure to form the pads.

4. Surface Treatment:

o Time Required: 1-2 hours

o The formed pads undergo surface treatments such as grinding and coating to enhance their smoothness and ink transfer capabilities.

Usage and Maintenance

Usage

1. Installation:

o Time Required: 5-10 minutes

o Pads are mounted onto the pad printing machine’s pad holder, ensuring they are securely fixed.

2. Ink Pick-Up:

o Time Required: 3-5 seconds per cycle

o The pad picks up ink from the cliché by pressing down with uniform pressure, ensuring an even distribution of ink.

3. Ink Transfer:

o Time Required: 5-7 seconds per cycle

o The pad transfers the ink from the cliché to the substrate by pressing down with controlled pressure and speed to avoid distortion or blurring.

Maintenance

1. Cleaning:

o Time Required: 5-10 minutes

o Regular cleaning with specialized cleaners or warm water is essential. Avoid strong acids or bases that can damage the silicone.

2. Storage:

o Pads should be stored in a dry, cool place away from direct sunlight and high temperatures to prevent aging. Proper storage can extend pad life to 6-12 months depending on usage.

3. Inspection:

o Time Required: 5-10 minutes per session

o Regularly inspect pads for wear and tear. Replace any pads showing signs of damage to maintain print quality.

Choosing the Right Pad Printing Machine Pad

Print Design Details

The complexity and detail of the design significantly influence pad selection. For intricate designs, pointed and harder pads are preferable due to their ability to transfer fine details accurately. For larger, less detailed designs, round or oval pads with medium or soft hardness are more suitable.

Substrate Material and Shape

The material and shape of the substrate also determine the type of pad to use. For substrates with irregular or contoured surfaces, soft pads are ideal due to their ability to conform to the surface. For flat or smooth surfaces, harder pads ensure precise and sharp image transfer.

Printing Environment

Environmental factors like temperature, humidity, and cleanliness affect pad performance. In high-temperature or humid environments, pads may deform or degrade faster. Choosing materials resistant to these conditions and maintaining a controlled environment can mitigate these issues.

Real-World Applications

1. Electronics Industry

In the electronics industry, where precision is paramount, pointed pads are often used for printing fine details on components such as circuit boards and small electronic devices. The hard, precise nature of these pads ensures that even the smallest details are transferred accurately.

2. Toy Industry

The toy industry frequently employs round or oval pads for printing large, colorful designs on toys. These pads are well-suited for covering large areas and ensuring even color distribution, making them ideal for vibrant, detailed graphics.

3. Promotional Products

For promotional products, where a variety of shapes and materials are used, medium hardness pads are commonly chosen for their versatility. They provide a balance between flexibility and precision, making them adaptable to different printing requirements.

Conclusion

Pad printing machine pads are integral to the success of the pad printing process. Their material, shape, and hardness directly impact the quality and efficiency of printing. By understanding the various types of pads, their manufacturing processes, and how to properly use and maintain them, businesses can achieve superior printing results. As technology and materials science advance, pad printing pads will continue to evolve, offering even greater precision and versatility for a wide range of applications. Through careful selection and diligent maintenance, these pads can significantly enhance the productivity and quality of printing operations across various industries.

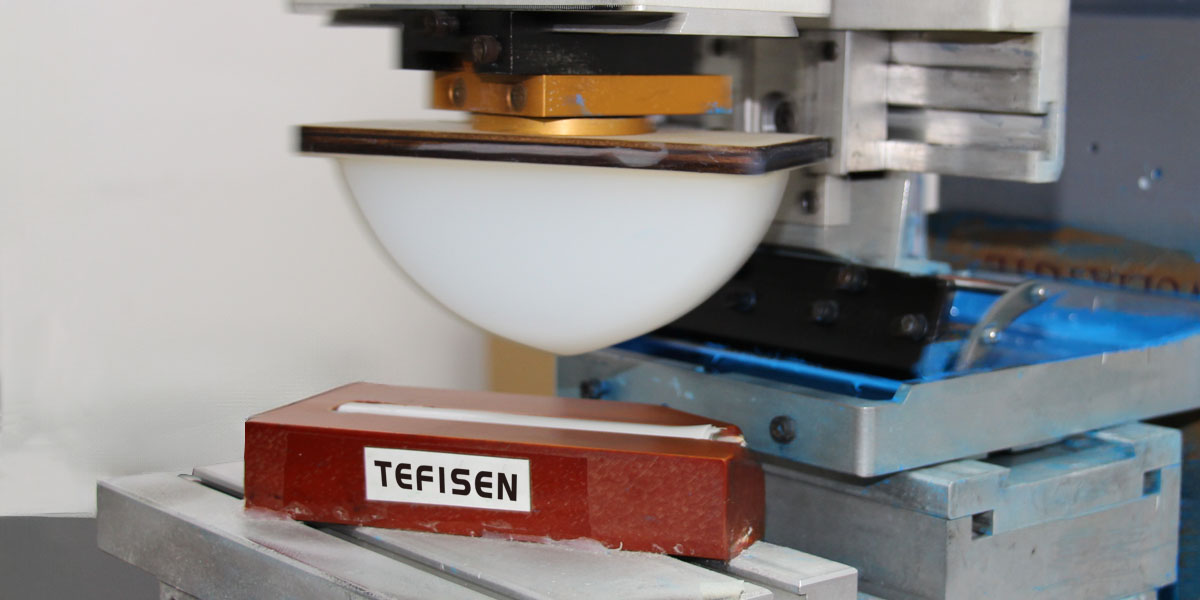

About Tefisen

Guangdong Tefisen Technology Co., Ltd. is a leading enterprise specializing in the research, development, production, and sales of pad printing machine pads and related printing equipment. Located in Guangdong Province, China, Tefisen boasts advanced manufacturing facilities and a highly skilled technical team dedicated to providing superior printing solutions. The company's products are widely used in industries such as electronics, toys, gifts, stationery, and household appliances, known for their exceptional quality and consistent performance. Committed to the principle of "quality first, customer foremost," Tefisen continually innovates and improves its offerings to meet the ever-evolving demands of the market. With a focus on technological advancement and customer satisfaction, Guangdong Tefisen is poised to remain at the forefront of the printing technology industry, delivering greater value to its clients worldwide.